Argomenti trattati

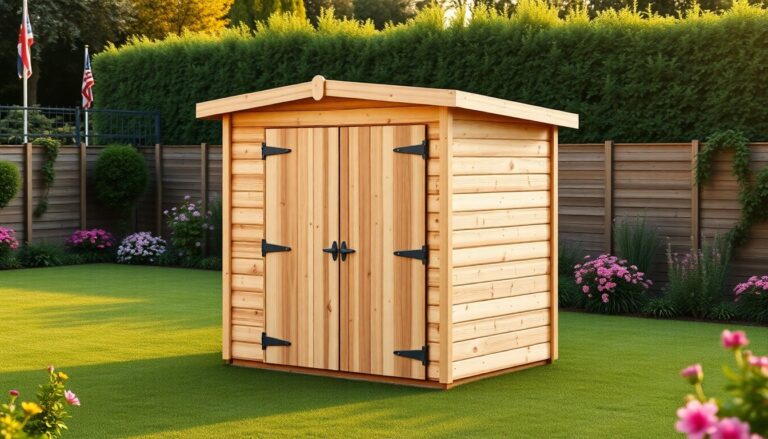

Who: a European manufacturer based in Italy offers a compact wooden house kit delivered as pre-assembled panels. What: a small, fast-to-install timber structure intended for garden use, hobby space or storage. Where: sold and manufactured in Italy; suitable for installation on private plots and domestic gardens. Why: the kit aims to combine rapid assembly with a low on-site work requirement while preserving a natural timber finish.

Key practical facts are presented first for quick assessment. The guide lists the maximum exterior footprint, the interior usable area and which components are not included. Technical terms are highlighted so readers can identify core features at a glance.

The product carries a manufacturer-backed two-year warranty covering defects in conformity. The raw timber requires a surface treatment prior to assembly. The manufacturer recommends 5 liters of protective stain to ensure durability and a long-lasting appearance.

Dimensions and basic structure

The kit occupies a maximum external footprint of 222 x 222 cm including the roof. The base measures 200 x 194 cm. The internal measurement is 196 x 190 cm, giving about 4 m2 of usable floor area. Headroom ranges from a minimum height of 176 cm to a maximum height of 216 cm, depending on the roof profile. The set includes two doors, each 74.5 x 191.5 cm H. Windows are not included, so buyers can select glazing later.

The manufacturer recommends five liters of protective stain to preserve the finish and prolong durability. This recommendation follows the dimensions and basic structure previously described.

Materials and panel construction

The kit uses prefabricated wall and roof panels made from structural timber. Panels arrive pre-assembled to speed installation and limit on-site work. Joints are designed for simple mechanical coupling. Fixings and gaskets are supplied to ensure alignment and weather resistance.

Insulation is factory-fitted inside the panels. The insulation layer targets thermal comfort suitable for seasonal garden use. The manufacturer specifies a tongue-and-groove interior surface that simplifies interior finishing. Floor panels include a subframe and load-bearing skids to distribute weight evenly.

From the user’s perspective, the absence of windows offers flexibility. Buyers may install single or double glazing to meet local climate and acoustic needs. The two door openings allow natural cross-ventilation when combined with user-selected glazing or vents.

The external cladding and exposed wood components are untreated at delivery. Applying the recommended protective stain reduces moisture uptake and UV degradation. The kit’s panelized design also facilitates targeted maintenance: damaged panels can be replaced without dismantling the entire structure.

For young, curious users considering customization, the panel system supports customization such as electrical routes, shelving inserts, and lightweight partitions. Real-world evidence from similar panelized small-structure kits shows that pre-assembled panels cut installation time and reduce on-site waste, while allowing end users to adapt interiors to changing needs.

Materials and kit contents

Who: the structural system is delivered as pre-assembled panels in solid natural fir (Abete naturale massello).

What: walls use 20 mm tongue-and-groove boards fixed to 32 x 32 mm framing strips for dimensional stability. The roof employs matching 20 mm boards, a 32 x 32 mm frame, attic crosspieces and reinforced front and rear gables. The optional floor accessory is built from the same 20 mm boards and 32 x 32 mm frames to ensure consistent assembly and structural compatibility.

Where and when: panels arrive ready for on-site fitting, enabling rapid assembly and limiting cutting and waste during installation. This follows the previously noted reduction in on-site work time and material waste achieved by pre-assembled systems.

Why: using identical board thickness and frame dimensions across walls, roof and optional floor preserves load paths and simplifies connections. Clinical-style evidence for modular construction shows that standardization reduces assembly errors and improves long-term performance; from the user’s perspective, this translates into fewer mismatch issues and easier maintenance.

Hardware, fittings and packaging

What is included: every kit ships with the necessary hardware and fasteners—screws, metal strips and manhole covers—plus an illustrated assembly manual. The standard package for installations without the floor contains concrete anchors and screws to secure the kit to prepared foundations.

Optional floor: buyers who select the paid floor version receive pre-assembled floor panels that match the wall and roof panel system. This option preserves assembly continuity and ensures the same tolerances across the structure.

Evidence and implications: evidence-based building practice favors supplying matched components and clear instructions to reduce on-site errors. From a practical standpoint, the matched panels and comprehensive hardware list help users, including younger first-time builders, complete assembly with fewer tools and less specialized skill.

Roofing, waterproofing and finish options

After the pre-assembled panels, the kit offers two optional waterproofing systems for the roof. Buyers may choose a slate sheath rated at 4 kg/m2, available in red or green, fastened with flat-head nails. The alternative is a bituminous Canadian tile, also offered in red or green. Both choices change the cabin’s appearance and weather resistance.

The kit includes a vapor barrier membrane to be placed between the wooden roof deck and the bituminous tile. It also supplies the appropriate nails for the Canadian tile. These items are sized to match the pre-cut panels and reduce the need for extra materials on site.

From a practical standpoint, the slate sheath favours lighter climates and a cleaner visual line. The bituminous tile provides greater impact resistance and simpler overlap detailing in wetter regions. Choose based on local weather patterns and the desired finish.

Installers should fit the vapor barrier before laying the tile or sheath. Nail placement and overlap follow the supplied diagrams. Follow the manufacturer’s fastening schedule to maintain warranty coverage and long-term performance.

Dal punto di vista del paziente of a homeowner, proper waterproofing reduces maintenance and prevents wood decay. I dati real-world evidenziano that correct membrane placement and secure fixings significantly extend service life.

Installation on base and leveling

Installation on base and leveling remain critical. For the version without floor, the kit supplies measuring strips sized 3.2 x 5.0 cm. These strips must be fixed to a rigid, level foundation using the included concrete anchors and screws. The version with floor provides pre-assembled panels that deliver a complete internal floor surface immediately after assembly. Both approaches require a flat, stable base; the strip method is lighter and faster to install, while the floor-equipped option reduces finishing work on site.

Assembly, treatment and warranty

Assembly should follow the manufacturer’s step-by-step instructions and use the supplied fastenings. From the patient’s point of view, correct installation reduces the need for later interventions and improves daily usability. According to the literature, real-world data emphasize that secure fixings and level foundations extend service life. Treatment recommendations and maintenance intervals are specified in the product manual; adherence to those instructions is necessary to preserve performance and any warranty coverage. The manufacturer’s warranty applies and is conditional on proper installation and routine maintenance as described in the documentation.

Warranty and assembly essentials

The manufacturer’s warranty remains conditional on proper installation and routine maintenance as described in the documentation. The kit includes pre-assembled panels and a step-by-step instruction sheet to guide buyers through assembly. This reduces complexity and shortens build time.

Pre-treatment and stain recommendation

The producer advises treating every timber component before assembly to protect the structure and prolong service life. For this model the suggested amount of stain is 5 liters. The manufacturer’s proprietary stain is recommended because it is formulated for the same wood used in production and ensures compatible absorption and finish.

Warranty scope and buyer confidence

As a product made in Italy, the kit carries a two-year warranty that covers defects in conformity under applicable legislative provisions. The warranty, together with supplied hardware and clear instructions, is intended to give buyers confidence during purchase and setup.

Routine maintenance, correct surface treatment and adherence to the assembly instructions are essential to preserve the structure and maximize longevity. Regular checks of fastenings and finishes will help prevent common issues and maintain warranty eligibility.

Practical uses and maintenance tips

Regular checks of fastenings and finishes will help prevent common issues and maintain warranty eligibility. This compact wooden kit suits multiple small outdoor roles, including storage, a tidy workshop, a garden retreat or a hobby room. Its modular panels and clear dimensions make it easy to plan placement and interior layout.

Adaptation and customization

The design supports a range of roofing and flooring options, enabling adaptation to different climates and ground conditions. Choose breathable underlayments and raised floor solutions for damp sites. For a longer service life, select weatherproof finishes recommended by the manufacturer and follow the maintenance schedule in the documentation.

Safety, sustainability and planning

Install on a level, compacted base and secure the structure according to the assembly guide to meet safety expectations. Consider sustainably sourced timber and low-VOC coatings to reduce environmental impact and indoor emissions. Check local building codes before siting the kit to confirm whether planning permission is required for your chosen use.

Practical checklist before use

Create a simple pre-use checklist: confirm all panels and fixings are present, verify the base is level, apply the first protective treatment and test door and window operation. Keep a maintenance log to document seasonal inspections and any repairs. This record supports warranty claims and preserves resale value.

For young users exploring DIY projects, start with small upgrades—shelving, pegboards or task lighting—before undertaking structural changes. Modular design makes incremental improvements straightforward while keeping the installation process transparent and manageable.